Washing Machine Spin Noise

Frigidaire, White Westinghouse spin noises....

Problem:

very irritating squealing sound when washer is spinning or coasting to a stop after the spin cycle.

Case:

- Snubber damage defective.

- Foreign material (sand/dust or grit) is on the base.

Solution:

- Replace the snubber.

- Clean base.

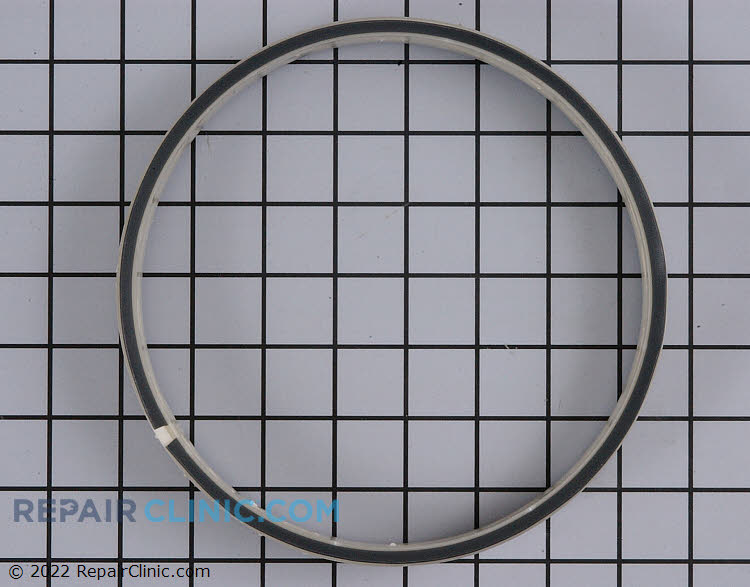

The snubber is a ring that is located between the convex (domed up) center portion of the base and the domed down center portion of the LEG & DOME ASSEMBLY.

The snubber has teflon strips at the top and bottom edges that slide easily on the base as well as the underside of the leg and dome assembly.

This system makes the machine very stable by providing isolation between the leg & dome assy. Which carries both the inner and outer tubs, as well as the main motor and transmission and the base; which is of course connected to the cabinet. This means that the machine is capable of spinning out of balance loads.

As simple as this system is, if one on the strips is bent or there is some foreign material on the base in the snubber area, the result can be an extremely obnoxious scratching or squealing sound that can make the consumer very unhappy.

A very similiar sound can be produced when the belt is worn but the difference is that a snubber noise can be produced during the spin cycle or when the cycle has finished and the spin tub is coasting to a stop. A worn belt noise can only be produced while the motor is actively engaged in spinning the spin tub. If it is discovered that the belt is worn and the base has black, shredded belt residue then it may not necessary to clean it out (belt residue generally will not cause a problem with the snubber). It will be necessary however, to find the cause of the belt failure.

The following procedure should be followed to diagnose and eliminate this condition:

Removing the snubber:

The base must be wiped whether the snubber is replaced or not. Any residue whether it is dust or grit of any kind (other than belt residue as noted above) can cause the objectionable sound to occur.

Remove the front service panel and place the timer in the spin cycle and start the machine. You want to try to duplicate the complaint. Inspect the base for sign of any foreign material. Lift the top panel up and over and lean it against the rear wall.

You will need a tool to raise the entire Leg & Dome Assembly (to which the main motor, tubs and transmission are attached). The machine will not need to be disassembled; the springs will not even be released.

Some Techs use a length of two-by-four" to raise the assembly. A pry-bar makes a superior tool when combined with a block of wood to act as a fulcrum (or pivot point).

Before raising the assembly, pull forward on it so that when you do raise it, the rear of the tub cover does not catch on the rear cabinet frame as it is being lifted.

Using your body weight, raise the assembly high enough to slide the snubber out. You will need to inspect the snubber for defects or damage. It is a good idea to be prepared with some sort of supports (like 3/4 inch pieces of wood) to slide between the lower edge of the assembly and the base to help support it if it were to slide off your pry-bar.

The teflon strips on upper and lower edges of the snubber must be perfectly smooth and undamaged in anyway.

The picture above shows the top strip is bent over. This would cause the distinctive "fingernails in blackboard" sound. Note also the arrow on the side of the snubber. When reinstalling or replacing the part, the arrow must be pointing upward.

Cleaning the base:

As was stated before, the base must be wiped out whether the snubber is replaced or not. A cloth wetted with denatured (camp stove) alcohol or rubbing alcohol will clean any residue, such as soap, or fabric softener off of the base and will also cut any waxes or oils that may have been missed by the factory, during assembly. An old cloth work glove would work well also. Make sure that the snubber area is wiped out well. Never oil the base to stop the snubber noise; (such as WD40 or silicone spray) may well stop the sound but will cause the assembly to slide to easily on the base and could cause damage to the sides of the cabinet from being hit by the tubs during an out-of-balance spin cycle. It could also cause the machine to "walk" from its position and cause a "banging" sound.

Tips:

Before installing a new snubber, have it out of it's packaging, with arrow positioned upward, and ready to be installed. While holding the assembly up, you will not have time to mess with tearing it out of it's bag.

When the job is completed, make sure to test the machine in the spin cycle to make sure that you were successful. You can even unbalance the tubs to test it.

When the job is done, make sure to reposition the machine to its original position and re-set the rear leveling legs.

Remember: Be careful !! - fingers do not grow back.