Maytag Bravos or Centennial VMW top-load washer error codes:

Reference Model: None

These error code explanations can help you troubleshoot a problem with your Maytag Bravos or Centennial VMW top-load washer.

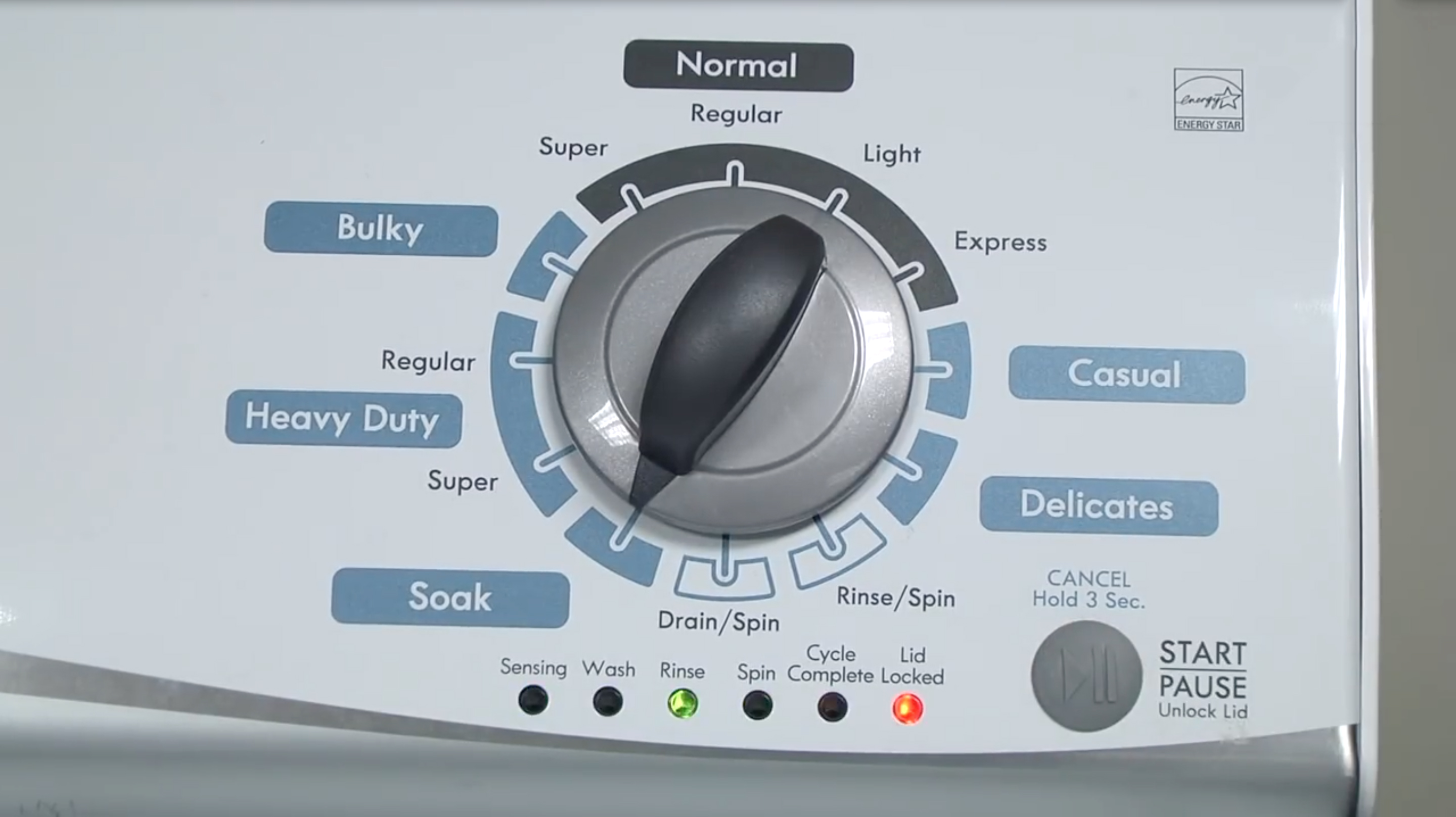

On models without a digital display, the fault code is signaled by blinking status lights.

| Code | Meaning | Possible Cause | Possible Parts |

| Lid Lock LED flashing | Indicates the control recorded one of the error codes shown below | Refer to the tech sheet (stored in the console) to enter the diagnostic test mode and recover the saved error code | |

| F0 E2 | Excessive suds | Use only HE (High Efficiency) detergent. Reduce the quantity of detergent to prevent excessive suds | HE detergent |

| F0 E4 | High water temperature in the rinse cycle | Make sure that fill hoses are properly connected. Check the resistance of the thermistor (temperature sensor). It should measure around 50K ohms (50,000 ohms) at 77 degrees. If the thermistor is defective, replace it | Thermistor |

| F0 E5 | Unbalanced load | Re-distribute the load inside the spin basket. If that doesn't help, then check the suspension rods and springs. If a suspension rod and spring is broken or damaged, replace all of the suspension rods and springs (the replacement part is a kit that has all 4 rods/springs) | Suspension rods/springs |

| F1 E1 | Main electronic control board failure | Unplug the washer. Check the wiring connections on the main electronic control board in the console. If the wiring connections are okay, then the main electronic control board will usually need to be replaced | Main electronic control board |

| F1 E2 | Motor control error on main electronic control board failure | Unplug the washer. Check the wiring connections on the main electronic control board and the drive motor. If the wiring connections are okay, then the drive motor windings will need to be checked for resistance. If the drive motor is bad, replace it. If the drive motor is okay, the main electronic control board will usually need to be replaced | Drive motor, Main electronic control board |

| F2 E1 | Stuck key | This code is for models with a digital display. One or more keys on the user interface were actuated for 15 seconds or longer. If a key is stuck and cannot be freed up then the user interface control will need to be replaced | User interface control |

| F2 E3 | Mismatch of main electronic control board and user lnterface control | This code is for models with a digital display. It typically occurs when an incompatible control component (Main Electronic Control board or User Interface control) is replaced in the console. Check the replacement part numbers and reorder the correct part | Main electronic control board, User interface control |

| F3 E1 | Water level pressure sensor fault | Unplug the washer. Check the air hose connection between the bottom of the tub and the water level pressure switch on the main electronic control board in the console. If no problems are found, then the main electronic control board (which includes water level pressure switch) will usually need to be replaced | Main electronic control board |

| F3 E2 | Inlet water temperature fault | Unplug the washer. Open the console and check the resistance through the thermistor circuit (black wires). It should measure around 50K ohms (50,000 ohms) at room temperature. If the thermistor is defective, replace it (the thermistor is a component in the inlet valve assembly wiring harness) | Inlet water valve wiring harness (this harness includes the thermistor) |

| F5 E1 | Lid switch fault | This code is displayed if Start is pressed with the lid open. If the lid switch on the lid lock/switch assembly isn't detecting the condition of the washer lid properly, then the lid lock/switch assembly will need to be replaced | Lid lock/switch assembly |

| F5 E2 | Lid lock fault | Unplug the washer. Check the lid lock/switch assembly for debris or an item that is interfering with the lock strike being engaged by the lid lock mechanism. If no interference is apparent, then the lid lock/switch assembly will usually need to be replaced | Lid lock/switch assembly |

| F5 E3 | Lid unlock fault | Unplug the washer. Lift the top panel of the washer to access the lid lock/switch assembly. Try to manually unlock the washer lid without breaking the lid lock/switch assembly and the lock strike. If the components are damaged, replace them. If the lid lock/switch assembly won't lock and unlock properly, replace it | Lid lock/switch assembly, Lock strike |

| F5 E4 | Lid not opened between cycles | If the washer is started several times without the lid ever being opened, then this code appears. If the lid is actually being opened between cycles but the control doesn't detect it, then the door lock/switch assembly will typically need to be replaced | Lid lock/switch assembly |

| F7 E1 | Basket speed sensor fault | See if the spin basket rotates freely. If not, then examine and replace any defective drive components. If the basket spins properly, unplug the washer and check the wiring connections on the shifter assembly. That component has the optical tachometer. If the wiring connections are okay, then that shifter assembly will usually need to be replaced | Drive system components, shifter assembly |

| F7 E5 | Shifter assembly fault | The main electronic control board cannot determine the position of the drive system shifter. Unplug the washer and check the wiring harness connections on the main electronic control board and the shifter assembly. If the wiring connections are okay, then the shifter assembly will usually need to be replaced | Shifter assembly |

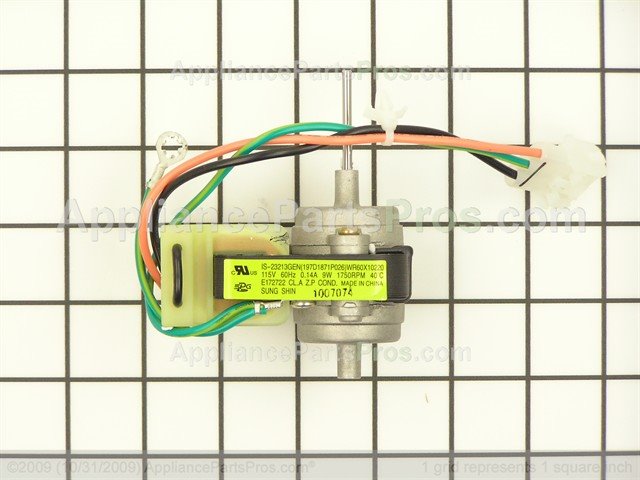

| F7 E6 | Motor fault | Unplug the washer and check the wiring connections on the drive motor. If the wiring connections are okay, then the drive motor will typically need to be replaced | Drive motor |

| F7 E7 | Motor is unable to reach target RPM | Rotate the spin basket to see if it spins freely. If not, then a garment could be stuck between the outer tub and the spin basket. A problem with drive components could also cause excess friction. Inspect the drive components and replace parts as needed | Drive system components |

| F8 E1 | Not filling or long fill time | Water isn't being detected as entering the washer. If the washer isn't filling, check the water supply faucets behind the washer to make sure that they are fully open. Check the fill hoses and inlet water valves. If the inlet water valve assembly is defective, replace it. If water is entering the machine but not being detected, then the main electronic control board (which includes the water level pressure switch) will usually need to be replaced | Inlet water valve assembly, main electronic control board |

| F8 E3 | Overflow condition | If the washer is overfilling, check the inlet water valves. If the valves are not shutting off water flow, then replace the inlet water valve assembly. If the washer isn't actually overflowing, then the main electronic control board (which includes the water level pressure switch) will typcially need to be replaced | Inlet water valve assembly, main electronic control board |

| F8 E5 | Hot and cold fill hoses are reversed | Check the fill hoses. If they are connected properly then the inlet water thermistor (temperature sensor) will probably need to be replaced. That component is part of the Inlet Water Valve Wire Harness | Inlet water valve wire harness |

| F9 E1 | Long drain time | The washer isn't draining after the drain pump runs for 10 minutes. Check the washer drain and the drain hose for clogs or restrictions. If the drain path is clear, unplug the washer and check the drain pump. If the drain pump is defective, replace it | Drain pump |

| Wash LED on | No fill or long fill | Water isn't being detected as entering the washer. If the washer isn't filling, check the water supply faucets behind the washer to make sure that they are fully open. Check the fill hoses and inlet water valves. If the inlet water valve assembly is defective, replace it. If water is entering the machine but not being detected, then the main electronic control board (which includes the water level pressure switch) will usually need to be replaced | Inlet water valve assembly, main electronic control board |

| Spin LED on | Long drain time | The washer did not drain after the drain pump has been running for 10 minutes. Check the washer drain and the drain hose for clogs or restrictions. If the drain path is clear, unplug the washer and check the drain pump. If the drain pump is defective, replace it | Drain pump |

If you own a Kenmore, Maytag or Whirlpool top-load washer with a vertical modular drive system, you have to calibrate the washer's electronic control board if you replace any of these parts:

- Electronic control board

- Drive motor

- Motor capacitor

- Tub suspension springs

If you don't calibrate the washer, the washer might not fill with the right amount of water for the load, or the washer might have frequently unbalanced loads.

Your Whirlpool, Maytag or Kenmore washing machine has a vertical modular drive system if it was made in 2010 or later, has a control dial for setting the wash load and stays locked whenever the washer is running.

How to calibrate a washer after a repair video

This video shows how to troubleshoot a blinking lid lock light on your top-load vertical modular washer. The lid lock light on VMW washers, made by Whirlpool, Kenmore and Maytag, will flash whenever there is a problem with the washer. The problem may not necessarily be a broken lid lock.

Learn about a few possible issues, including the actuator motor, and see how to check the error codes on your washer to find out what the problem is.

How to troubleshoot flashing lid lock errors on a vertical modular washer video

Maytag Washing Machine Repair and Maintenance Parts

Related Links

- Maytag Bravos Washing Machine Transmission, Brake & Clutch Parts

- Maytag Bravos Washing Machine Suspension & Shock Absorption Parts

- Maytag Bravos Washing Machine Circuit Board & Timer Parts

- Maytag Bravos Washing Machine Pump Parts